Mini Laboratory Extruder

-

Bench top machine -

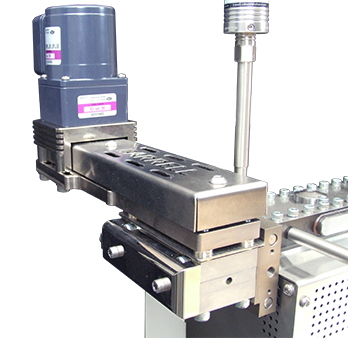

Model-MK3B – 12.7 mm (1/2 inch) Twin Screw Extruder

Bench top machine – specifications & info

Counter Rotation – closely intermeshing counter rotating screw design

Excellent Mixing

Minimal Material Waste/Minimal Free Volume

Minimal Pulsating

This equipment has been specially designed for diverse and precise mini extruding processes.

With the capabilities to achieve the maximum chemistry characteristics with minimum batch quantities.

Special attention has been made to ensure precise smooth output motion of the extrusions, which is particularly important when performing low volume output rates for single fibre/strand extrusions etc.

Optional accessories available e.g. Melt Pump and Tooling.

Features

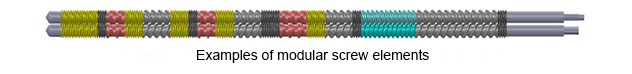

- Modular screw elements (Flexibility via User configurable screw element design)

- Counter-rotation

- Maximum pressure- 100 bar

- Maximum output- 1500 ml/Hour

- Maximum temperature- 375 degrees Celsius

- Rpm- 0 to 350

- Dimensions: Footprint – 600mm x 1000mm x 450mm (height from base to top of barrel)

- Minimum batch size- 5 cc (20 cc is better)

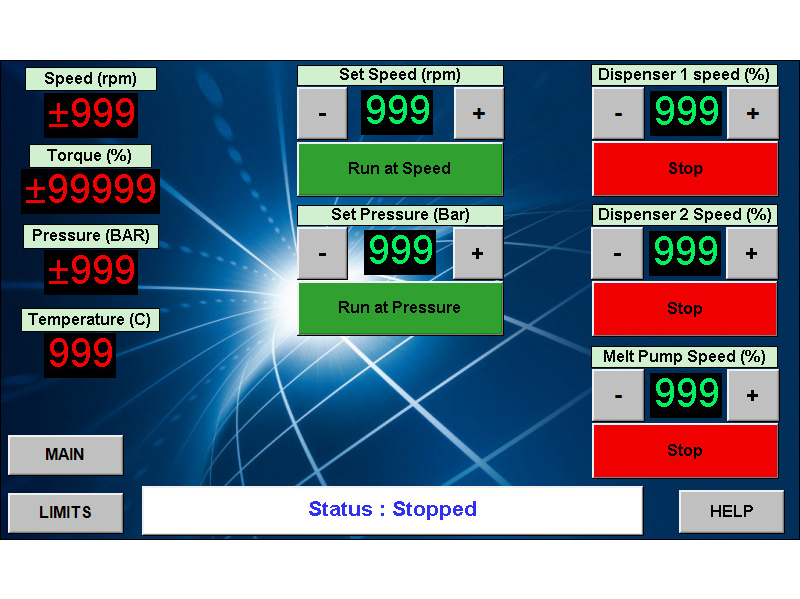

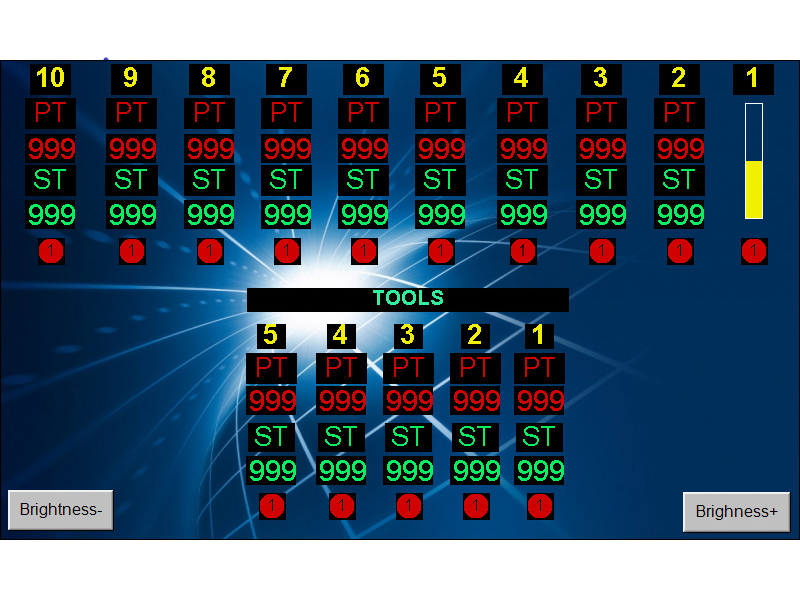

- Touch screen controls

More product images

-

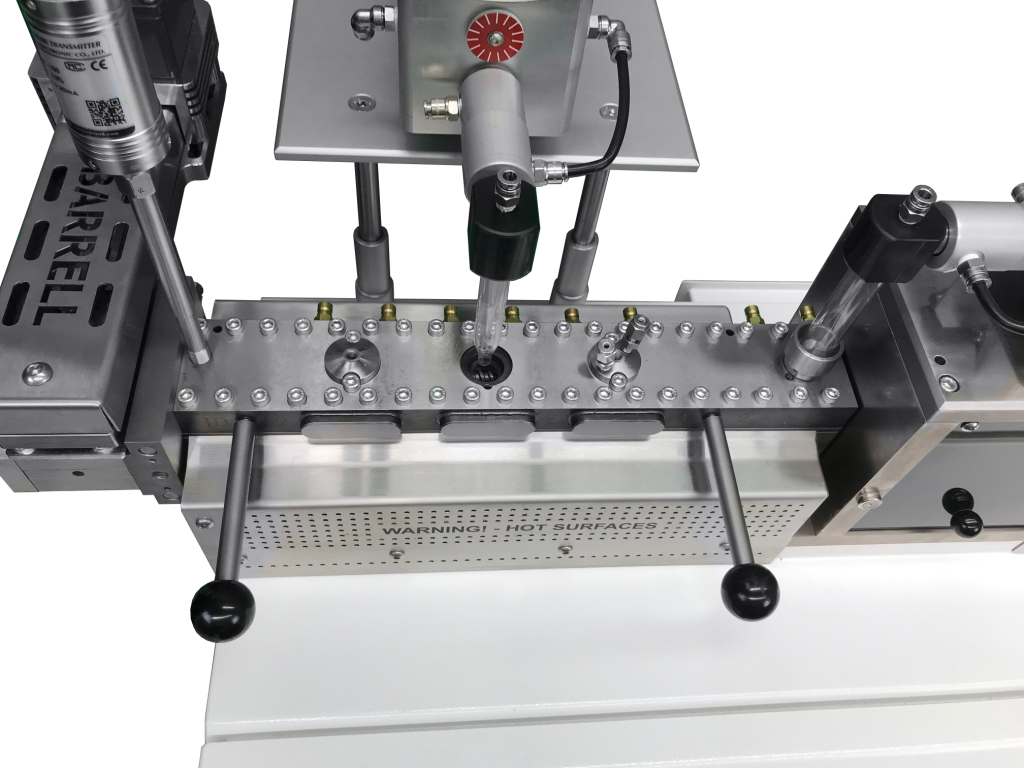

View of Extruder with 2 dispensers and melt pump

mounted in a vented enclosure. -

View of co-extruding

Melt pump/pot + co-ex tooling + twin screw Extruder

Dimensions

Width x Depth x Height: 1000mm x 600mm x 450mm (note: height from barrel top to base)

Power source: 380-415 VAC 3Ph @ 10A (supplied with a 20A plug)

Weight: 80kg not including options