Dispensers

Custom Dispensers

-

Air/gas stream dispenser -

Dosing stepper motor dispenser -

Peppecorn dispenser (Dosing with stepper motor) -

Pressure sealed dispenser

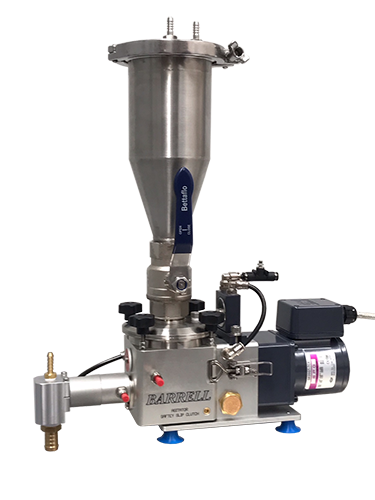

The Micro Dispenser is designed for dispensing powders and granules with variable flow rates from as low as 15 cc/hour to 2000 cc/hour. Popular in applications for laboratory, chemistry and extruding industries the Micro Dispenser features digital speed controller and provisions for temperature control.

Custom-built dispensers available upon request

Features

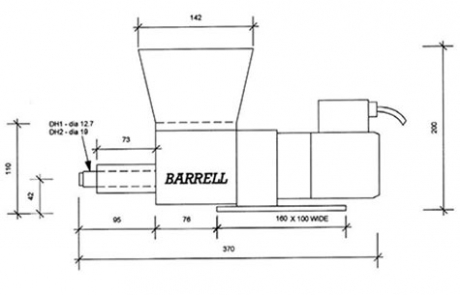

- Modular Dispensing Head DH02 = Screw Barrel DIA 19mm x 16mm

- Variable Speed Motor Drive

- Interchangeable Gearbox

- Downspout air or gas blower pipe

- Pneumatic air vibrator

- Fine, Medium and Course Augers (screws)

- Provisions for temperature control (cooling off dispenser body and barrel)

- Feed Rate Combination = from 15 cc/hr minimum to 2000 cc/hr maximum (actual range will depend on gearbox ratio selected) See motor/gearbox ratios feed rates chart (Note: Lower feed rates can be achieved upon special request)

- Finger safety – agitator drive safety clutch

*Granules should not exceed 1.5 mm DIA (Special screws/augers can be made for larger granules upon request)

The Barrell Micro Dispenser was designed specifically for minimal feed rates with a maximum linear and volume accuracy, achieving volumes as low as 15 cc/hr. This dispenser has been designed volumetric specific because at such low volumes of material a gravimetric system would struggle to achieve a consistent linear accuracy. This dispenser is capable of dispensing difficult to manage powders and granules.

Accuracy

Tight tolerances of screw and barrel to maximise material transfer producing excellent linear and volumetric accuracy.

Temperature Control

The dispensing head and screw barrel have an inbuilt porting system enabling the entire dispensing head and screw barrel to be temperature controlled. This will enable stabilisation of material and combat against any heat that may be generated by friction. This also enables the screw and barrel to run at tight tolerances when dispensing heat sensitive materials.

Modular Systems: Dispensing Head (DH) and Motor Drive (MD) selection

The modular system enables flexibility in choosing dispenser set up and cleaning

Motor Drive: Frequency controller supplied by 240 volt. The controller has a digital display in 0.1 Hz increments. (110 – 120 volt optional)

Downspout Blower Pipe

Blower pipes will assist in gently blowing powder off the screw when exiting the machine (particularly if static is present). The blower pipe can also be used to add nitrogen gas if needed.

Safety

The micro dispenser also features a slip clutch system on the agitator for finger safety.

Feeder Screws and Barrels

Feeder screws and barrels are made from 316 stainless steel. A selection of feeder screws for dispensing powders or granules are available. Custom screws can be supplied to suit customer requirements.

Dispensing Head

The dispensing head is fully machined anodised aluminium, hosting bearings, seals, stainless steel agitator, screw and barrel and mini hopper and is ported for cooling (temperature control).

More images

-

Micro Dispenser with sealed hopper / Dehumidifier -

Dispenser Hoppers -

(Optional) Sealed Hopper / Dehumidifying -

(Optional) Dispenser Speed Controller -

Micro Dispenser – Dimensions